Software Neo-Plate

Important notice: this product may delay the rest of the order.

Software for pressure platform.

Enhance the functions of your old T-Plate / T-Plate S platform.

Ref. xxxx

Improve the performance of your T-PLATE / T-PLATE S platform

FUNCTIONS IT PERFORMS

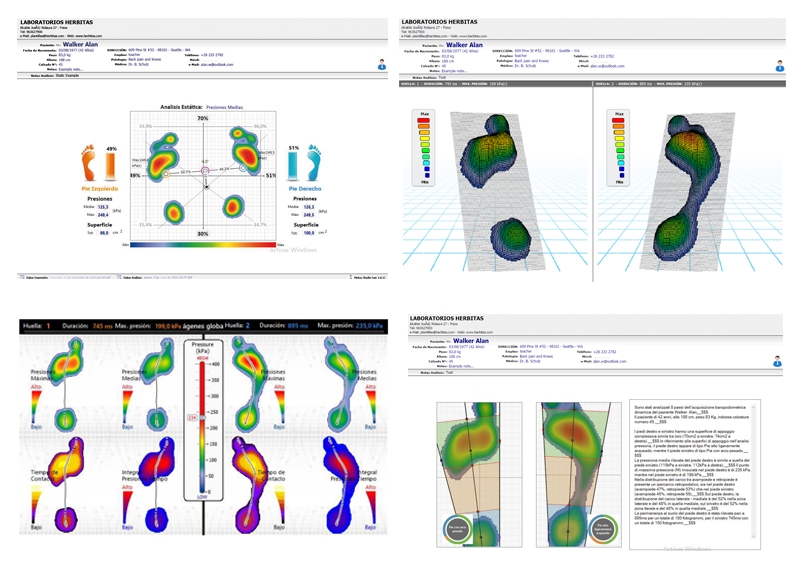

Static Analysis:

Instantaneous or average 5-second shot. Load difference forefoot/backfoot, right/left foot and by quadrants.

Quantification of pressure centre position deviation. Automatic report writing.

Dynamic Analysis:

Visualization of pressures, contact time, average pressures and integral time/contact Coordinated graphics with animation. Video recording. Automatic report writing. Display of average measurement with respect to unlimited steps. Visualization of arc type.

Posturological analysis:

Length, surface and integral of both. Deviation from normality. Romberg index. Fourier Transforms.

Posture analysis:

Image analysis from 4 perspectives of body position. Analyses different deviations in inclination and length.

This type of analysis can perfectly replace the different systems of video analysis of the market.

GENERAL REMARKS

It is the most advanced and complete platform on the market. It is compatible with Digital Podoscope/Scanner ,and with various types of software.

The automatic report is greatly improved in terms of the information it provides, and in the way it is expressed. It also allows to include more comments that can be either hidden or printed to the client.

It incorporates "One Touch" printing with which we can quickly print the complete report to the patient, choosing all the options of pages to print as well as selecting those that interest us the most. Likewise, with the same function we can create a single PDF with all the information.

The database is much more efficient (SQL format as opposed to the previous Paradox) and can be debugged from the same programme by the user without the need for a technician. It also calculates the body mass index.

The possibility of configuring the system up to 500Hz allows analysis even during the race, without losing information.

Finally, it is compatible with CAD/CAM manufacturing through the Easy Cad software.