Graduated Scalpel Handle

Only %1 left

SKU

-

Podiatry graduated scalpel handle by Dimeda, made of stainless steel.

Various models.

From

€6.03

Description

The graduated Dimeda scalpel handle features a millimeter scale from 0 to 6cm and is made of stainless steel.

Check its high quality and precision!

USAGE INDICATIONS FOR SCALPEL HANDLES:

- Its graduation facilitates measurement and marking during clinical examination.

- Class I medical device.

- Reusable. Allows sterilization.

TECHNICAL CHARACTERISTICS:

BRAND: Dimeda

MATERIAL: Stainless steel

STERILIZABLE: Sterilizable product. Reuse allowed

NET WEIGHT: Model No. 3: 22g | Model No. 4: 26 g

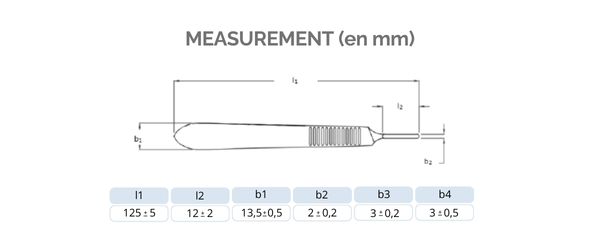

MEASUREMENTS: Total length: 125mm ± 5mm | Total width: 13,5mm ± 0,5mm | Total height: 3mm ± 0.5mm

COMPATIBLE SCALPEL BLADE: Model No. 3 is compatible with scalpel blades No. 11 to 15. Model No. 4 for scalpel blades No. 18 to 25 and also for No. 34 and 36.

CONTENTS: 1 plastic bag with 1 scalpel handle

STORAGE:

- Store at room temperature in a dry place.

- Protect from heat, intense light, and dust.

WARNINGS:

- Professional use.

- The instrument must be cleaned, disinfected, and sterilized by the clinician before first use and after each use.

CLEANING AND CARE:

Manual preliminary cleaning:

- Initially, it must be hand washed with neutral soap.

- In the operating room, the most apparent dirt should be removed as soon as possible to avoid embedding that can lead to corrosion.

- Long processing times should be avoided (<1h).

- Dry cleaning is preferable as medical devices may corrode if immersed for long periods in solutions.

- If the dry process is insufficient, it will be necessary to wash them with cold water (<40°C), including cavities, grooves, and hard-to-reach holes that must be washed with pressurized water. Avoid leaving unwashed areas. A soft plastic brush can be used.

- Thoroughly dry with an absorbent cloth that leaves no residue or with compressed air.

Cleaning and disinfection:

- Immerse the products in a solution of distilled water with an appropriate disinfectant in an ultrasonic bath or tank.

- Follow the instructions provided by the disinfectant product manufacturer to select the washing program, temperature, and time.

- Clean instruments with movable joints in the open position or by moving the joints to avoid "shadow areas". Follow the manufacturer's instructions for disassembling detachable instruments.

- The instruments must be fixed with minimal spacing between them in the cleaning container and overlapping must be avoided to prevent damage to the products from collisions.

- After completing the disinfection program, wash the products with plenty of cold distilled water, thoroughly insisting on the cavities, grooves, and hard-to-reach holes of the instrument, if possible with pressurized water.

- Thoroughly dry with an absorbent cloth that leaves no residue or with compressed air.

Sterilization:

- Sterilize the products taking into account the corresponding national requirements. Product sterilization must be carried out in a suitable sterilization container according to DIN EN ISO 11607-1 and EN 868 standards.

- Sterilization must be carried out using a pre-vacuum fractional process with the following parameters: 134°C, 5 minutes waiting time, 3 pre-vacuum cycles. Vacuum drying for at least 20 minutes.